top of page

Recent Posts

Archive

Tags

DEC MINE DESIGN & MINE SCHEDULING COURSES!!

For those who don't have the software but would like exposure to mine design and scheduling, and fully understand the life of mine cycle....

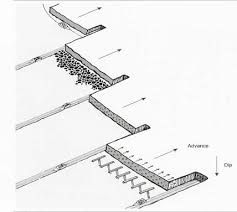

MINING METHOD OF THE WEEK - SUBLEVEL STOPING!!

This method is really a combination of several different methods of stoping. The figure is an illustration of the method, and shows half...

MINING ROCKSTAR OF THE WEEK - BERYL!!

Beryl is a relatively rare silicate mineral with a chemical composition of Be3Al2Si6O18. It is found in igneous and metamorphic rocks in...

SHOWCASE COPPER MINE OF THE WEEK - GRASBERG MINE

Grasberg mine in the Papua province of Indonesia ranked as the world’s tenth largest copper mine by reserve. The mine’s open pit and...

MINERAL PROCESSING METHOD OF THE WEEK - DRYING!!

The removal of water from solid materials by thermal drying plays a significant role in modern mineral processing. A great number of...

WORLD'S BIGGEST FRONT-END LOADERS - KOMATSU WA900!!

With a bucket capacity of 11.5m³ to 13m³ and operating weight of 107.3t, the Komatsu WA900-3E0 wheel loader with 856hp (638kW) engine is...

MINING METHOD OF THE WEEK - SIDE STOPING AND BREAST STOPING!!

Side stoping is an extreme of combination stoping in which the working face of the stope is vertical. The face is parallel to the raises...

ONLINE MINING COURSE FOR SCHOLARS, NON-GRADUATES OR DIPLOMATS!!

Don't have a university degree or diploma, but want to further your career in mining and hit that next promotion...? Don't have the means...

MINING ROCKSTAR OF THE WEEK - BENITOITE!!

Benitoite is an extremely rare mineral that is best known for being the official state gemstone of California. It is a barium titanium...

SHOWCASE MINE OF THE WEEK - JUBILEE DIAMOND MINE!!

Jubilee, also known as the Yubileyny diamond mine, located in Sakha (Yakutia), Republic of Russia, is the biggest diamond mine in the...

bottom of page