top of page

Recent Posts

Archive

Tags

CORPORATE GROUP TRAINING & COURSES - WHITTLE!!

Have a group of employees that need basic training in terms of mine planning software? Or perhaps a refresher course to get those rusty...

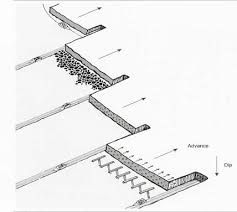

MINING METHOD MONDAY - SAW-TOOTH BACK STOPING!!

This method of carrying the back in an overhand stope is shown at position G in the figure below. It is claimed that it makes drilling...

MINE DESIGN BASICS FRIDAY - RATIO vs PERCENT!!

I tend to get confused when it comes to expressing ramp gradients in a ratio format vs percentage format. Below is a quick and easy...

CONGRATS SEPT'19 GROUP!!

A very warm congratulations to Jaco, Tim, Lukona and Lizanne from Sishen and Kolomela mines for completing the Mine Planning Basics Short...

HAULSIM PRODUCTIVITY SIMULATIONS!!

Are you 100% confident that your Excel calculations are correct in determining fleet numbers? Are your roads accurately set-up in terms...

MINE PLANNING BASICS FRIDAY - WHITTLE YOU BEAUTY!!

Doing a pit optimisation for a client, I realised you can utilise 2 different beneficiation plants by cleverly setting up the...

MINE SCHEDULING!!

know the feeling... when you're losing precious time because of fighting the software instead of running iterations and scenarios... You...

MINING ROCKSTAR OF THE WEEK – ILMENITE!!

Ilmenite is a common accessory mineral in igneous rocks, sediments, and sedimentary rocks in many parts of the world. Apollo astronauts...

MINE DESIGN!!

How sure are you that your mine designs have the minimum number of switchbacks? Have you tested the impact of having one switchback less,...

MINING METHOD MONDAY - SIDE STOPING AND BREAST STOPING!!

Side stoping is an extreme of combination stoping in which the working face of the stope is vertical. The face is parallel to the raises...

bottom of page